Mercedes Rim Straightening: Enhancing Performance and Safety

Mercedes rim straightening is a specialized process that corrects deformities caused by impacts or i…….

In the realm of automotive engineering, precision and aesthetics are paramount. One specialized service that has gained significant attention in recent years is Mercedes rim straightening—a meticulous process aimed at restoring and enhancing the integrity and visual appeal of vehicle wheels. This article delves into the intricate world of Mercedes rim straightening, exploring its definition, global impact, technological innovations, regulatory landscape, challenges, and future prospects. By the end, readers will have a comprehensive understanding of this critical aspect of automotive care and its far-reaching implications.

Definition: Mercedes rim straightening is a specialized service that involves correcting distortions and deformities in vehicle wheels, primarily those made by Mercedes-Benz. It is a meticulous process designed to restore the wheel’s structural integrity, improve its appearance, and ensure optimal performance.

Core Components:

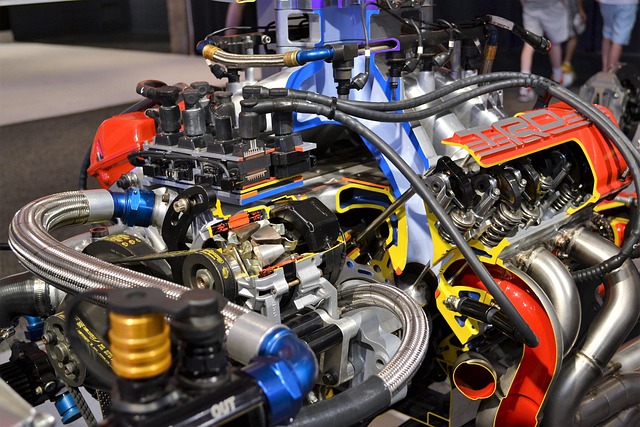

Wheel Inspection: The process begins with a thorough inspection of the rim to identify any distortions, bends, or deformities. Advanced diagnostic tools are employed to measure the wheel’s dimensions accurately.

Pre-Treatment: Depending on the severity of the damage, the rim may undergo cleaning, decontamination, and surface preparation to remove dirt, debris, or existing repair residues.

Straightening Technique: This is the heart of the process. Utilizing state-of-the-art machinery, such as hydraulic presses and specialized jigs, skilled technicians apply controlled force to straighten the rim back to its original specifications.

Precision Grinding (if needed): In cases of severe deformation, a precise grinding process may be employed to remove excessive material and restore the wheel’s curvature to its original design.

Final Inspection and Quality Control: After straightening, each wheel undergoes rigorous testing to ensure it meets strict quality standards before being returned to the vehicle or offered for sale as a refurbished option.

Historical Context: Mercedes-Benz, renowned for its luxury and engineering excellence, has long set benchmarks in automotive manufacturing. As vehicles became more specialized and high-performance, the need for precise wheel alignment and repair grew. Over time, Mercedes rim straightening evolved from a basic repair technique to a highly sophisticated process, incorporating advanced technologies to achieve unparalleled precision.

Mercedes rim straightening has transcended geographical boundaries, becoming a global phenomenon with varying regional influences:

| Region | Trending Factors | Market Dynamics |

|---|---|---|

| North America | Increasing demand for custom wheels and high-end vehicles. | Strong market for refurbished wheels, particularly among performance car enthusiasts. |

| Europe | Stricter safety regulations and advanced wheel design complexity. | High adoption rate of straightening services due to stringent quality standards. |

| Asia Pacific | Rapidly growing luxury car market and a preference for premium brands. | Rising demand for professional wheel repair and restoration services. |

| Middle East | Expensive vehicle ownership and a culture of luxury customization. | Significant investment in high-end rim straightening facilities and technology. |

These trends highlight the global nature of Mercedes rim straightening, with each region contributing unique dynamics to its growth and development.

The market for Mercedes rim straightening services is dynamic and multifaceted:

Original Equipment Manufacturers (OEMs): Mercedes-Benz and other luxury car manufacturers often outsource rim straightening to specialized workshops, ensuring that their wheels meet the highest standards before delivery.

Aftermarket Services: Independent repair shops, automotive spas, and mobile service providers offer rim straightening as a premium service, catering to vehicle owners seeking restoration or customization.

Refurbished Wheel Market: Straightened rims are often resold as refurbished options, providing cost-effective alternatives to purchasing new wheels.

The economic viability of Mercedes rim straightening is evident through:

High Profit Margins: Skilled labor and advanced equipment contribute to substantial profit margins for specialized workshops, making it an attractive investment opportunity.

Growing Demand: The increasing popularity of custom wheel designs, high-performance vehicles, and a global culture of luxury customization drive demand for professional rim straightening services.

Franchising Opportunities: Successful rim straightening businesses can expand through franchising models, leveraging their expertise and reputation in new markets.

Technological innovations have played a pivotal role in transforming Mercedes rim straightening from an art to a science:

Computer Numerical Control (CNC) Machinery: CNC machines enable precise control during the straightening process, ensuring consistent and accurate results. These advanced systems can handle complex wheel designs with remarkable efficiency.

3D Scanning Technology: 3D scanners capture detailed measurements of distorted rims, providing a digital blueprint for precise restoration. This technology ensures that every curve and contour is accurately replicated.

Automated Wheel Repair Systems: Automated systems streamline the grinding process, minimizing human error and improving productivity while maintaining exceptional quality.

Real-Time Feedback Systems: Advanced sensors provide real-time feedback during straightening, allowing technicians to make adjustments on the fly for optimal results.

The regulatory landscape surrounding Mercedes rim straightening varies across jurisdictions but generally focuses on ensuring consumer safety, product quality, and environmental considerations:

Safety Standards: Rims must meet strict safety standards regarding material composition, structural integrity, and dimensional accuracy to ensure vehicle and passenger safety.

Environmental Regulations: Proper disposal and recycling of wheel materials are mandated in many regions to minimize environmental impact.

Product Liability: Workshops performing rim straightening may be subject to product liability laws, requiring them to maintain thorough records and ensure the quality of their work.

Certification and Training: Skilled technicians often require specialized training and certifications to perform rim straightening, ensuring they possess the necessary expertise.

Despite its numerous benefits, Mercedes rim straightening faces several challenges and criticisms:

Cost Considerations: The process can be expensive due to the labor intensity and advanced technology involved. This may deter some vehicle owners from pursuing rim straightening, especially for minor distortions.

Misconceptions about Durability: Some customers perceive straightened rims as temporary solutions, unsure of their long-term reliability. Educating clients on the durability and structural integrity of straightened wheels is essential.

Lack of Standardization: Variations in rim design across different Mercedes models can make standardization challenging, requiring specialized equipment and expertise for each unique wheel style.

Strategies to Overcome These Issues:

Transparent Communication: Workshops should provide clear information about the process, costs, and expected outcomes to build trust with customers.

Educational Initiatives: Industry associations and manufacturers can collaborate on educational campaigns to dispel misconceptions and highlight the long-term benefits of rim straightening.

Standardized Training Programs: Developing comprehensive training programs for technicians can ensure consistency in service quality across different models and workshops.

Overview: A renowned automotive restoration shop in California specializes in luxury car wheel repair, including Mercedes rim straightening. They have achieved remarkable success by combining traditional craftsmanship with advanced technology.

Approach: The workshop utilizes a multi-step process involving 3D scanning, CNC machining, and hand finishing. They invest heavily in training their technicians to ensure precision and consistency.

Results: This business has built a reputation for restoring wheels to like-new condition, attracting high-end clients. Their success lies in combining traditional expertise with modern technology, offering a unique and sought-after service.

Scenario: A mobile rim straightening service based in Germany caters to the needs of busy vehicle owners who prefer convenience. They offer on-site repairs at customer locations.

Strategy: The company employs a fleet of fully equipped vans, each containing state-of-the-art straightening machinery. They prioritize quick turnaround times and provide same-day service for urgent cases.

Achievements: This mobile service has gained popularity among corporate clients and individuals with busy schedules, filling a niche in the market. Their success demonstrates the versatility and demand for rim straightening services beyond traditional repair shops.

The future of Mercedes rim straightening appears promising, with several emerging trends and growth areas:

Advanced Materials: The development of lightweight, durable materials will continue to influence wheel design, presenting new challenges and opportunities for straightening techniques.

Autonomous Repair Processes: Automation will play an increasingly significant role, with robotic systems taking on more tasks, improving efficiency and reducing labor costs.

Global Expansion: As the demand for luxury vehicles continues to rise globally, rim straightening services are expected to expand into new markets, particularly in Asia Pacific and emerging economies.

Sustainability Focus: Environmental concerns will drive innovation in recycling and sustainable wheel manufacturing practices, impacting the overall rim straightening industry.

Mercedes rim straightening is more than just a repair service; it is an art that combines precision engineering, advanced technology, and a deep understanding of automotive aesthetics. As vehicles become increasingly complex and design elements more intricate, the role of skilled rim straighteners will remain indispensable. By addressing structural integrity, enhancing visual appeal, and ensuring optimal performance, this specialized service contributes significantly to the overall value and longevity of Mercedes-Benz wheels.

Q: How do I know if my Mercedes wheels need straightening?

A: Signs include noticeable distortions, uneven tire wear, or a visually distorted wheel appearance. Professional inspection is the best way to determine if straightening is required.

Q: Is rim straightening expensive?

A: Costs can vary, but advanced technology and skilled labor contribute to higher expenses. Transparent pricing from workshops helps customers understand the value of the service.

Q: Can straightened rims be trusted for long-term use?

A: Absolutely! Straightened rims are designed and tested to meet stringent quality standards, ensuring they provide reliable performance over the vehicle’s lifespan.

Q: Are there any environmental concerns associated with rim straightening?

A: Proper disposal and recycling of materials are essential. Many workshops adopt eco-friendly practices, contributing to sustainability in the automotive industry.

Mercedes rim straightening is a specialized process that corrects deformities caused by impacts or i…….

Mercedes rim straightening is a specialized, precise process that demands advanced equipment and tec…….

Mercedes rim straightening repairs damaged vehicle wheels, restoring them to their original shape an…….

Mercedes rim straightening is a cost-effective way to restore damaged wheels to their original facto…….

Mercedes rim straightening is a vital service for restoring damaged wheels, improving safety, and en…….

Mercedes rim straightening is a specialized service crucial for high-performance Mercedes-Benz vehic…….